To score the coating on bilaminated panels .

Machines: Horizontal panel sizing machines that allow vertical adjustment of the scorer in relation to the panel sizing saw blade kerf .

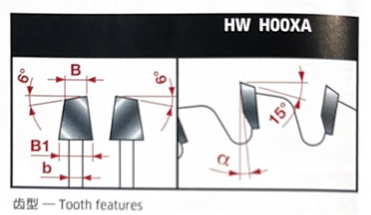

Features: ATB 6°tooth with positive cutting angle.

Material: Bilaminated chipboard or MDF

D | B | b | d | Z | α | NL | 机器 |

毫米 | 毫米 | 毫米 | 毫米 |

|

| NL | Machines |

mm | mm | mm | mm |

|

|

|

|

80 | 3.1-4.3 | 2.2 | 20 | 12 | 0° |

| Casadei |

80 | 3.1-4.3 | 2.2 | 22 | 12 | 0° |

|

|

100 | 3.1-4.3 | 2.5 | 20 | 20 | 0° |

|

|

100 | 3.1-4.3 | 2.2 | 22 | 24 | 0° |

| Schelling |

100 | 3.1-4.3 | 2.2 | 20 | 24 | 0° |

|

|

110 | 3.1-4.3 | 2.2 | 22 | 24 | 0° |

|

|

110 | 3.1-4.3 | 2.2 | 20 | 24 | 0° |

|

|

115 | 3.1-4.3 | 2.2 | 22 | 24 | 0° |

|

|

115 | 3.1-4.3 | 2.2 | 20 | 24 | 0° |

|

|

115 | 2.8-4.0 | 2.8 | 45 | 24 | 0° |

| SCM |

120 | 2.8-4.0 | 2.2 | 20 | 24 | 0° |

| Schelling |

120 | 3.1-4.3 | 2.2 | 22 | 24 | 0° |

|

|

120 | 3.1-4.3 | 2.2 | 20 | 24 | 0° |

|

|

120 | 3.1-4.3 | 2.2 | 22 | 24 | 0° |

|

|

120 | 3.4-4.6 | 2.5 | 20 | 24 | 0° |

|

|

120 | 3.1-4.3 | 2.2 | 20 | 24 | 0° |

| SCM |

125 | 3.1-4.3 | 2.2 | 200 | 24 | 0° |

| Panhans-Schelling |

125 | 3.1-4.3 | 2.2 | 22 | 24 | 0° |

| Martin |

125 | 3.1-4.3 | 2.5 | 20 | 24 | 0° |

| Panhans-Schelling |

125 | 3.4-4.6 | 2.2 | 20 | 24 | 0° |

|

|

125 | 3.4-4.6 | 2.2 | 45 | 24 | 0° |

|

|

125 | 4.3-5.5 | 3.2 | 20 | 24 | 0° |

| Panhans-Gabbiani |

125 | 4.3-5.5 | 3.2 | 45 | 24 | 0° |

| Giben-Homag |

125 | 4.5-5.7 | 3 | 20 | 24 | 0° |

|

|

125 | 4.5-5.7 | 3 | 45 | 24 | 0° |

| Giben-Homag |

140 | 3.1-4.3 | 2.2 | 16 | 28 | 8° | 1/6/33 | Scheer |

140 | 3.4-4.7 | 3 | 45 | 24 | 8° |

|

|

140 | 4.3-5.5 | 3.2 | 45 | 28 | 8° |

| Euromac |

140 | 4.5-5.7 | 3 | 45 | 24 | 8° |

|

|

145 | 4.3-5.5 | 3.2 | 45 | 30 | 8° |

| Hansol Machine |

150 | 3.1-4.3 | 2.2 | 30 | 36 | 8° |

| SCM |

150 | 3.4-4.7 | 2.2 | 30 | 36 | 8° |

| SCM |

150 | 4.3-5.6 | 3.2 | 30 | 36 | 8° |

| SCM,Verry |

150 | 4.3-5.6 | 3.2 | 45 | 36 | 8° |

| SCM,Holzma,Homag,Haisung Woodworking Machinery |

150 | 4.5-5.8 | 3 | 30 | 36 | 8° |

| SCM |

150 | 4.5-5.8 | 3 | 45 | 36 | 8° |

| SCM |

125 | 3.1-4.3 | 2.5 | 20 | 24 | 0° |

| Panhans-Schelling |

125 | 3.4-4.6 | 2.2 | 20 | 24 | 0° |

|

|

125 | 3.4-4.6 | 2.2 | 45 | 24 | 0° |

|

|

125 | 4.3-5.5 | 3.2 | 20 | 24 | 0° |

| Panhans-Gabbiani |

125 | 4.3-5.5 | 3.2 | 45 | 24 | 0° |

| Giben-Homag |

125 | 4.5-5.7 | 3 | 20 | 24 | 0° |

|

|

125 | 4.5-5.7 | 3 | 45 | 24 | 0° |

| Giben-Homag |

140 | 3.1-4.3 | 2.2 | 16 | 28 | 8° | 1/6/33 | Scheer |

140 | 3.4-4.7 | 3 | 45 | 24 | 8° |

|

|

140 | 4.3-5.5 | 3.2 | 45 | 28 | 8° |

| Euromac |

140 | 4.5-5.7 | 3 | 45 | 24 | 8° |

|

|

145 | 4.3-5.5 | 3.2 | 45 | 30 | 8° |

| Hansol Machine |

150 | 3.1-4.3 | 2.2 | 30 | 36 | 8° |

| SCM |

150 | 3.4-4.7 | 2.2 | 30 | 36 | 8° |

| SCM |

150 | 4.3-5.6 | 3.2 | 30 | 36 | 8° |

| SCM,Verry |

150 | 4.3-5.6 | 3.2 | 45 | 36 | 8° |

| SCM,Holzma,Homag,Haisung Woodworking Machinery |

150 | 4.5-5.8 | 3 | 30 | 36 | 8° |

| SCM |

150 | 4.5-5.8 | 3 | 45 | 36 | 8° |

| SCM |

160 | 3.1-4.3 | 2.2 | 20 | 36 | 8° |

| Langzauner |

160 | 3.4-4.6 | 2.2 | 25.4 | 36 | 8° |

|

|

160 | 4.3-5.5 | 3.2 | 25.4 | 36 | 8° |

|

|

160 | 4.3-5.5 | 3.2 | 30 | 36 | 8° |

| Langzauner |

160 | 4.3-5.5 | 3.2 | 45 | 36 | 8° | 3/11/70 | Giben |

160 | 4.3-5.5 | 3.2 | 55 | 36 | 8° | 3/6/84+3/7/66 | Gabbiani-SCM |

160 | 4.3-5.5 | 3.2 | 60 | 36 | 8° | 3/7/80 |

|

160 | 4.5-5.7 | 3 | 45 | 36 | 8° | 3/11/70 | Giben |

160 | 4.5-5.7 | 3 | 55 | 36 | 8° | 3/7/66+3/9/72 | Gabbiani |

175 | 4.3-5.5 | 3.2 | 75 | 36 | 8° |

| Wonpoong |

180 | 3.1-4.3 | 2.2 | 16 | 42 | 8° | 1/6/33 | Scheer |

180 | 3.4-4.6 | 2.2 | 25.4 | 36 | 8° |

|

|

180 | 4.3-5.5 | 3.2 | 20 | 28 | 8° |

| Schelling-Anthon |

180 | 4.3-5.5 | 3.2 | 30 | 28 | 8° | 2/7/42+2/10/60 | Panhans-Holzer |

180 | 4.3-5.5 | 3.2 | 20 | 36 | 8° |

| Schelling-Anthon |

180 | 4.3-5.5 | 3.2 | 30 | 36 | 8° | 2/7/42+2/10/60 | Holzher,Nanxing,KDT |

180 | 4.3-5.5 | 3.2 | 45 | 36 | 8° |

| Holzma |

180 | 4.3-5.5 | 3.2 | 50 | 36 | 8° | 3/13/80 | Giben |

180 | 4.5-5.7 | 3 | 20 | 36 | 8° |

| Schelling-Anthon |

180 | 4.7-5.9 | 3.5 | 45 | 36 | 8° |

| Holzma |

180 | 5.1-6.3 | 3.5 | 55 | 36 | 8° | 3/7/66 | Gabbiani |

180 | 5.7-6.9 | 4 | 20 | 36 | 8° |

| Anthon-Holzma |

200 | 4.3-5.5 | 3.2 | 20 | 36 | 8° | 2/11/66+2/10/60+2/9/62 | Schellin |

200 | 4.3-5.5 | 3.2 | 22 | 36 | 8° |

|

|

200 | 4.3-5.5 | 3.2 | 30 | 36 | 8° | 2/9/60+2/10/60 | Scheer |

200 | 4.3-5.5 | 3.2 | 45 | 36 | 8° |

| Holzma,Hyundai Sangi |

200 | 4.3-5.5 | 3.2 | 50 | 36 | 8° | 2/7/80+3/13/80 | Giben,KDT |

200 | 4.3-5.5 | 3.2 | 65 | 36 | 8° | 2/9/100+2/9/110 | Gabbiani |

200 | 4.3-5.5 | 3.2 | 80 | 36 | 8° | 2/14/110 | Gabbiani |

200 | 4.3-5.5 | 3.2 | 75 | 36 | 8° |

| Hyundai Sangi |

200 | 4.5-5.7 | 3 | 22 | 36 | 8° |

|

|

200 | 4.5-5.7 | 3 | 65 | 36 | 8° | 2/8.5/100 | Gabbiani |

200 | 4.7-5.9 | 3.5 | 20 | 36 | 8° | 2/11/66 |

|

200 | 4.7-5.9 | 3.5 | 22 | 36 | 8° |

|

|

200 | 4.7-5.9 | 3.5 | 30 | 36 | 8° | 2/9/60 | Scheer |

200 | 4.7-5.9 | 3.5 | 45 | 36 | 8° |

| Holzma |

200 | 4.7-5.9 | 3.5 | 65 | 36 | 8° | 2/9/100+2/9/110 | Selco |

200 | 5.4-6.6 | 3.8 | 20 | 36 | 8° |

|

|

200 | 5.7-6.9 | 4 | 45 | 36 | 8° |

| Holzma |

200 | 5.7-6.9 | 3.5 | 65 | 36 | 8° | 2/9/110 |

|

200 | 6.1-7.3 | 4.2 | 20 | 36 | 8° | 2/11/66 | Schelling,Scheer |

215 | 4.3-5.5 | 3.2 | 50 | 42 | 8° | 2/7/80+3/15/80 | Giben |

215 | 4.5-5.7 | 3.2 | 50 | 42 | 8° | 3/15/80 | Giben |

220 | 6.3-7.5 | 4.4 | 20 | 36 | 8° | 2/11/66 | Schelling |

250 | 3.1-4.3 | 2.2 | 30 | 54 | 8° |

|

|

250 | 4.3-5.5 | 3.2 | 50 | 48 | 8° | 3/13/80 | Giben |

250 | 4.3-5.5 | 3.2 | 30 | 48 | 8° | 2/10/60 |

|

280 | 4.3-5.5 | 3.2 | 30 | 48 | 6° | 2/10/60 | Panhans |

300 | 4.3-5.5 | 3 | 65 | 48 | 6° | 2/9/100+2/9+110 | Selco |

300 | 4.3-5.5 | 3.2 | 30 | 48 | 6° | 2/11/75+2/13/94+2/11/73 | Schelling |

300 | 4.3-5.5 | 3.5 | 50 | 48 | 12° | 3/15/80 | Giben |

300 | 4.3-5.5 | 3.2 | 65 | 72 | 12° | 2/9/110+2/9/100 | Selco |

300 | 4.3-5.5 | 3.2 | 80 | 72 | 12° | 2/14/110 |

|

300 | 4.7-5.9 | 3.5 | 65 | 48 | 6° | 2/9/110 | Selco |

320 | 4.3-5.5 | 3 | 45 | 48 | 12° |

|

|

320 | 4.3-5.5 | 3.2 | 45 | 48 | 12° |

|

|

340 | 4.7-5.9 | 3.5 | 45 | 72 | 12° | 3/14/65 | Holzma |